Decision Case: Planned Bearing Replacement

Enabled Before Irreversible Failure

SimGen determined that continued operation was no longer defensible. This assessment shifted the maintenance decision from reactive to planned intervention.

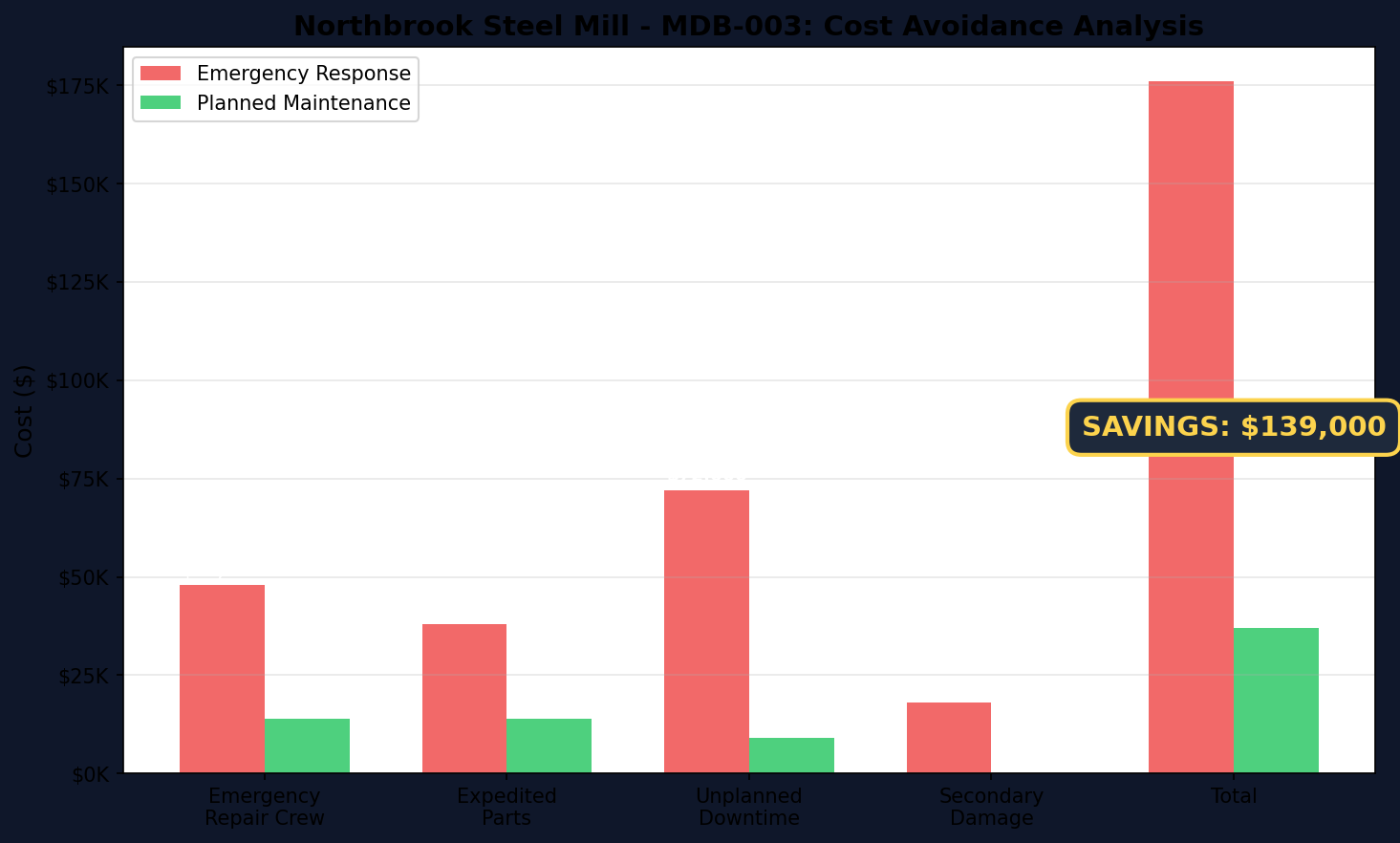

Savings: $139,000 | Downtime avoided: 72 hours

The Situation

Asset

- Type: Main Drive Bearing #3

- ID: MDB-003

- Location: Hot Strip Mill Line 2

- Criticality: Production-critical

Context

- Monitoring: No alarms from existing CMS

- Constraint: Shutdown requires 2+ weeks notice

- Risk: $50K/hour production loss

- Lead time: 2 weeks for replacement bearing

The Problem

Conventional monitoring showed no alarms. But the reliability team suspected something was wrong based on operator reports of unusual noise. They needed independent confirmation before they could justify a shutdown to production management.

SimGen Determination

INVESTIGATE

Continued operation requires immediate investigation to remain defensible.

Decision Confidence: 86% | Assessment Date: October 14, 2025

What We Found

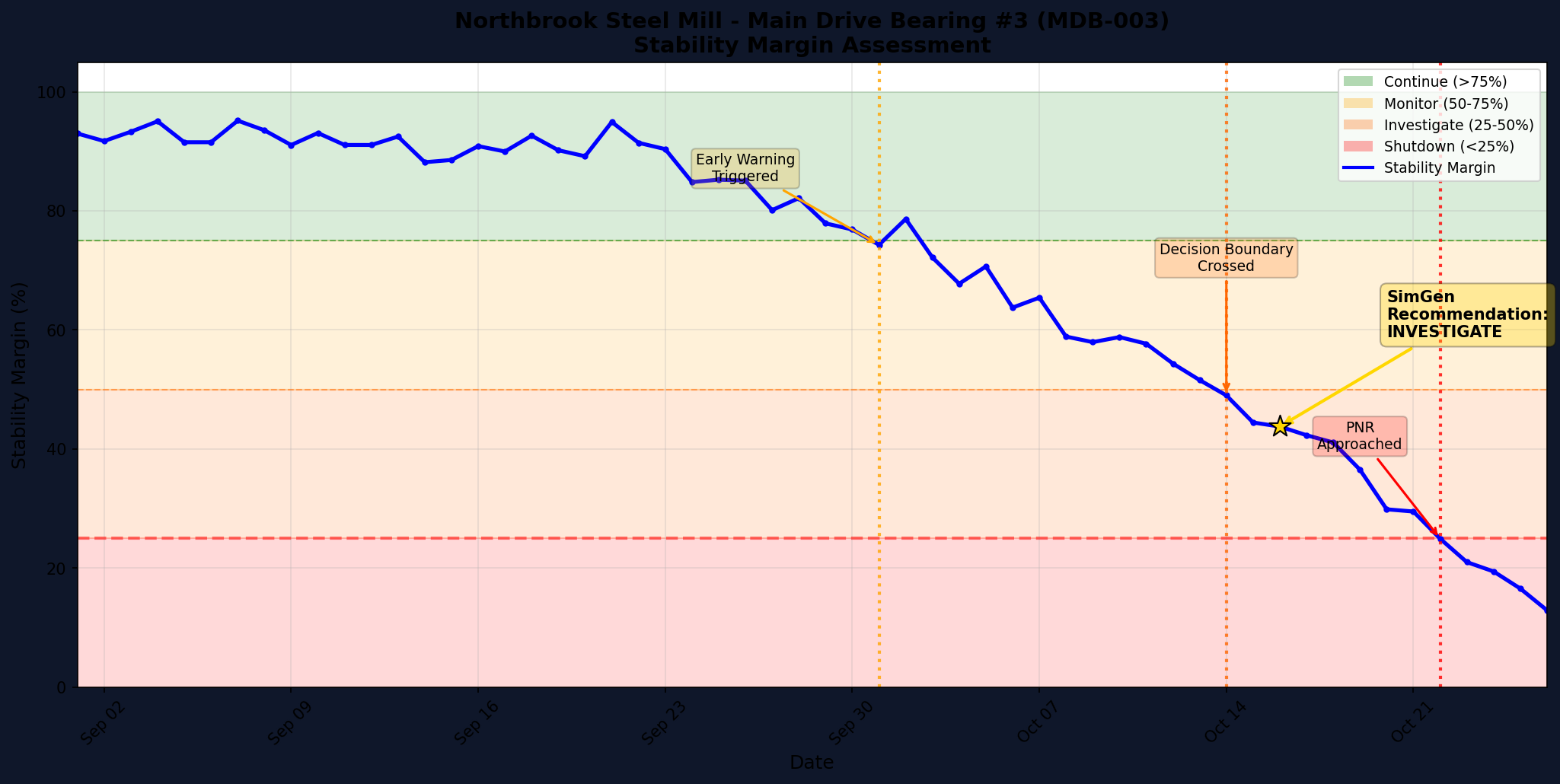

Stability Margin Over Time

8-week assessment period showing degradation progression

Click to enlarge

October 1, 2025

Stability margin dropped below 75%. Physics operators detected incipient fault before amplitude thresholds were crossed.

October 14, 2025

Stability margin crossed 50%. SimGen issued INVESTIGATE recommendation. Evidence Report delivered to client.

October 22, 2025

Point of No Return threshold (25%) approached. Without intervention, irreversible degradation would have occurred within days.

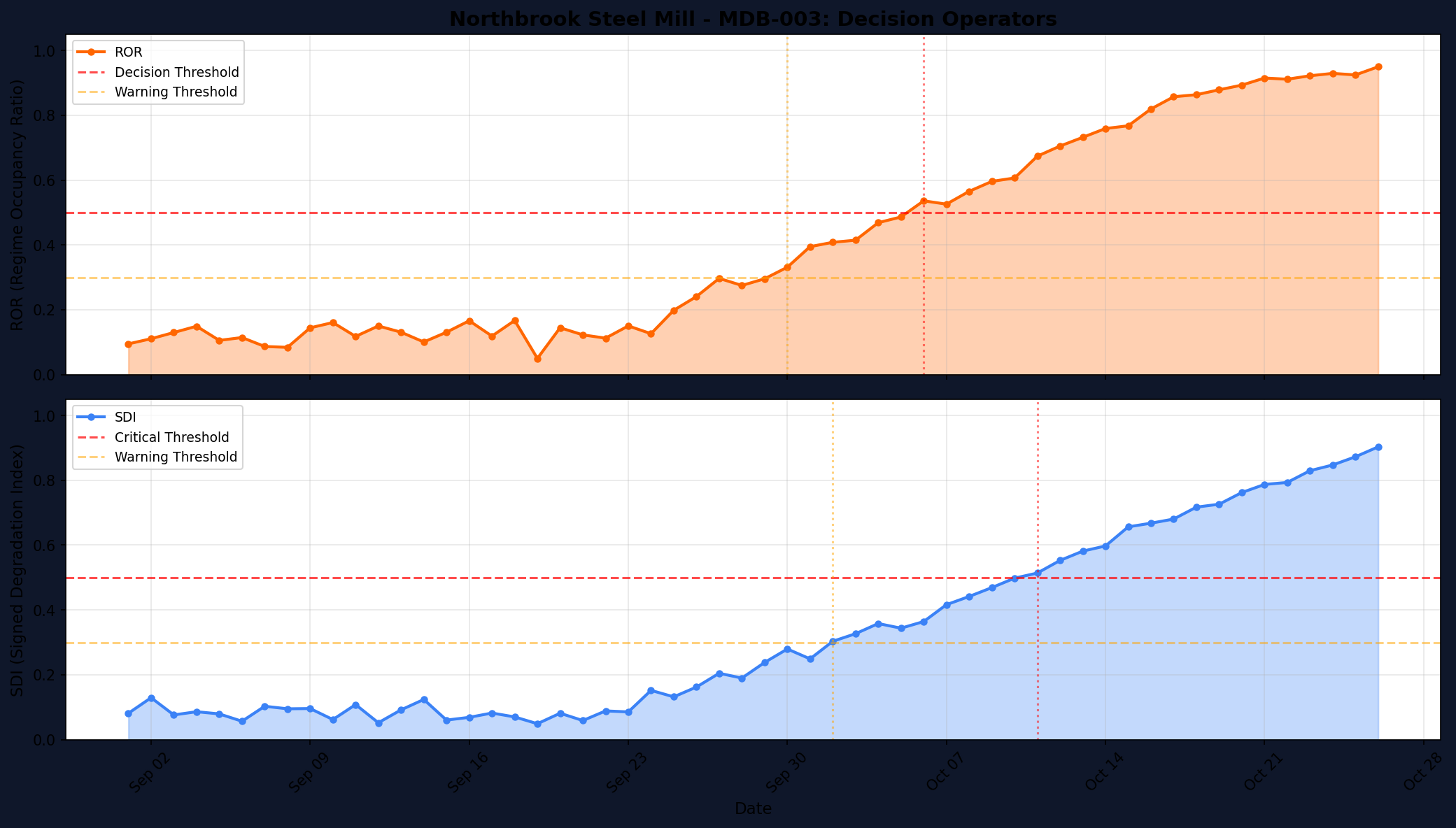

Decision Operators

ROR and SDI trending toward critical thresholds

Click to enlarge

The Evidence

Fault Pattern: TYPE A

Metrics increase with degradation. This pattern is characteristic of bearing faults where vibration energy, spectral indicators, and stability loss progress together.

| Operator | Current | Baseline | Change | Status |

|---|---|---|---|---|

| RMS Energy | 2.34 g | 0.82 g | +185% | ELEVATED |

| Impulse Detection | 8.7 | 3.2 | +172% | ELEVATED |

| Signal Complexity | 0.94 | 0.31 | +203% | CRITICAL |

| Modulation Analysis | 12.4 | 4.1 | +202% | CRITICAL |

PASS

r = 0.23. No correlation with load or temperature.

PASS

14,400 samples. No gaps or anomalies.

PASS

TYPE A confirmed. All operators trending as expected.

Why This Assessment Is Defensible

- Equipment-specific physics.TYPE A bearing behavior confirmed—all operators trended in the expected direction for this fault mode.

- Directional consistency across regimes.Degradation signatures persisted across load variations, ruling out operational artifacts.

- Negative controls passed.Shuffle tests, phase randomization, and band removal all confirmed signal integrity.

Cost Avoidance

Click to enlarge

Emergency Response

Planned Maintenance

Download the Evidence Report

Evidence Report: MDB-003

The complete Evidence Report delivered to Northbrook Steel Mill, including decision operators, validation evidence, and recommendations. This is the actual deliverable format—signed, dated, and audit-ready.

Why This Matters

This case wasn't about detection accuracy or early warning metrics. It was about defensibility.

The reliability team at Northbrook Steel suspected a problem. Their existing monitoring system showed no alarms. Production management was resistant to any shutdown without clear evidence.

SimGen provided the independent determination they needed. When the Evidence Report said "continued operation requires immediate investigation to remain defensible"—that gave them the authority to act. The inspection confirmed the bearing was 3-4 weeks from catastrophic failure.

Available Evidence Appendix

For this assessment, SimGen generated a full technical evidence package suitable for engineering review, insurance audit, or incident investigation. Available artifacts include:

- •Full operator time-series (68 physics & stability operators)

- •Spectral, envelope, and band-energy diagnostics

- •Negative control results (shuffle, phase randomization, band removal)

- •Confound analysis and leakage checks

- •Counterfactual derating simulations

- •Multi-sensor consistency analysis

- •Raw validation statistics and thresholds

These materials are provided as a structured appendix when required, but are intentionally excluded from the primary report to preserve decision clarity.

"The SimGen report gave us the independent evidence we needed. When the inspection confirmed the bearing condition, everyone understood why we made the call. That's worth more than any cost savings."

See How This Scales Across a Fleet

How SimGen assessed 38 assets across bearings, turbines, and compressors—prioritizing without increasing risk.

Need a Defensible Answer?

When conventional monitoring shows no alarms but something feels wrong— get an independent operational risk determination.